Rotator module version 3.1

This revision is from 2014/05/04 21:43. You can Restore it.

Components of Multi rotator controller server

Version 3.1 in addition to the 3.0 version only circuit to stabilize the voltage measured azimuth - AREF compensates for slight decrease voltage at relay switching, so there is no need of external power supply to measure the azimuth.

Planting plan

Part list

| P1,P2 | strip 9 pins |

| P3,P4 | strip 13 pins |

| P5 | pin array_3x2 |

| R4,R6,R7,R8 | k510 ohm |

| S1,S2,S3 | tact led sw |

| U1 | LCD-16x2 |

| U3 | Preset encoder |

| C1,C2,C3,C4 | capacity 4n7 |

| CON1 | pin array 5x2 |

| D1,D2,D3,D4 | diode 1n4148 |

| J1 | DB15 female connector |

| L1,L2 | inductor 100uH |

| R1,R2,R3,R5 | resistor 1k |

| RV1 | potentiometer 1k |

| U2 | ArduinoNano3.0 |

| P6 | pin_array_3x2 |

| RL1,RL2,RL3 | Relay |

| Q1,Q2,Q3 | transistor BC547 |

Assembly gallery

✔ All components

❏ Solder R4 R6 R7 R8 (marked in blue)

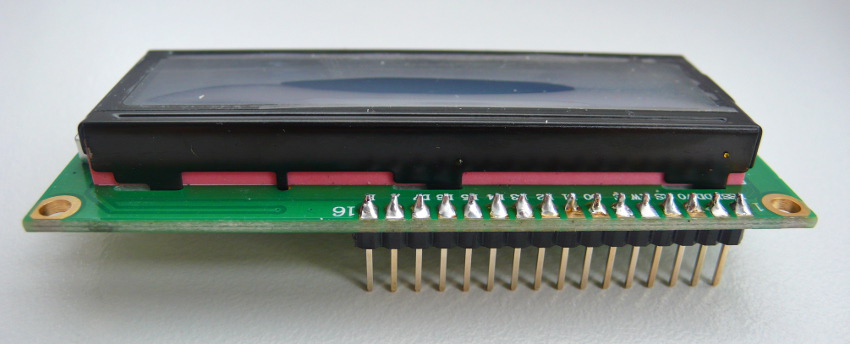

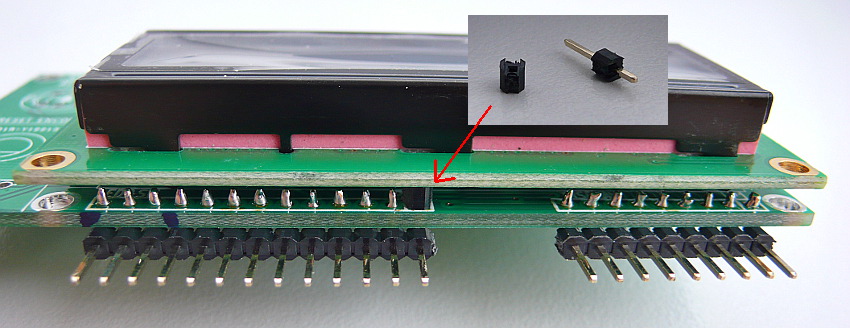

❏ 13 and 9 pins 90° strip

❏ 16 pins strip to LCD

❏ Insulating spacer washers between LCD and PCB

❏ LCD module to PCB

❏ CW, CCW and START switch (marked in blue) and preset encoder, Now front panel is final

❏ Next R1 R2 R3 R5 (marked in black) and R9 solder on main board

❏ D1 D2 D3 D4 (marked in red)

❏ L1 L2 (marked in green)

❏ Q1 Q2 Q3

❏ C1 C2 C3 C4 and C5 between C4 and L1

❏ 6 pins of brake sw, Inputs connector, R9, DIL cocketfor Arduino NANO

❏ F15 connector, three relay, Arduino nano

❏ last solder front panel via pin strip

Firmware

- configure Arduino firmware by K3NG

- download stable or unstable and doc

- custom pins.h

- Enable External Analog reference

- in unstable code

#define OPTION_EXTERNAL_ANALOG_REFERENCE //Activate external analog voltage reference (needed for RemoteQTH.com unit)

- in stable code activate this function with insert analogReference(EXTERNAL); to arduino code before analog_az = analogRead(rotator_analog_az); in master .ino file

analogReference(EXTERNAL); analog_az = analogRead(rotator_analog_az); - Enable LCD Display -> (by delete // at the three lines.)

#define FEATURE_LCD_DISPLAY #include <LiquidCrystal.h> LiquidCrystal lcd(lcd_4_bit_rs_pin, lcd_4_bit_enable_pin, lcd_4_bit_d4_pin, lcd_4_bit_d5_pin, lcd_4_bit_d6_pin, lcd_4_bit_d7_pin);

- Change the Baud rate to 9600 (at K3NG source code its 115.k baud the preset)

#define SERIAL_BAUD_RATE 9600

Connect Rotator (DB15 female) and power inputs

Phase jumper (5+6 CON1) change relay function between DC (change phase voltage) and AC (change direction).

Pin 3 in CON1 - input 5V stabilized voltage from power board This pin may be connected with pin4 CON1, then the voltage measurement uses a common 5V voltage from the power supply module.

The entire module can be powered from USB only, but there is a voltage drop, it is better to use an external source, or a DC/DC converter.