Rotator module version 3.3

This revision is from 2016/03/29 11:27. You can Restore it.

- Power

- Connect DC Rotator (DB15 female) and power inputs

- Connect AC Rotator (DB15 female) and power inputs

- Use with original control box

- Two wire azimuth potentiometer hardware addon from DM2RM

- Ten turn azimuth potentiometer (one turn used)

- Control software

Components of Multi rotator controller server

Part list

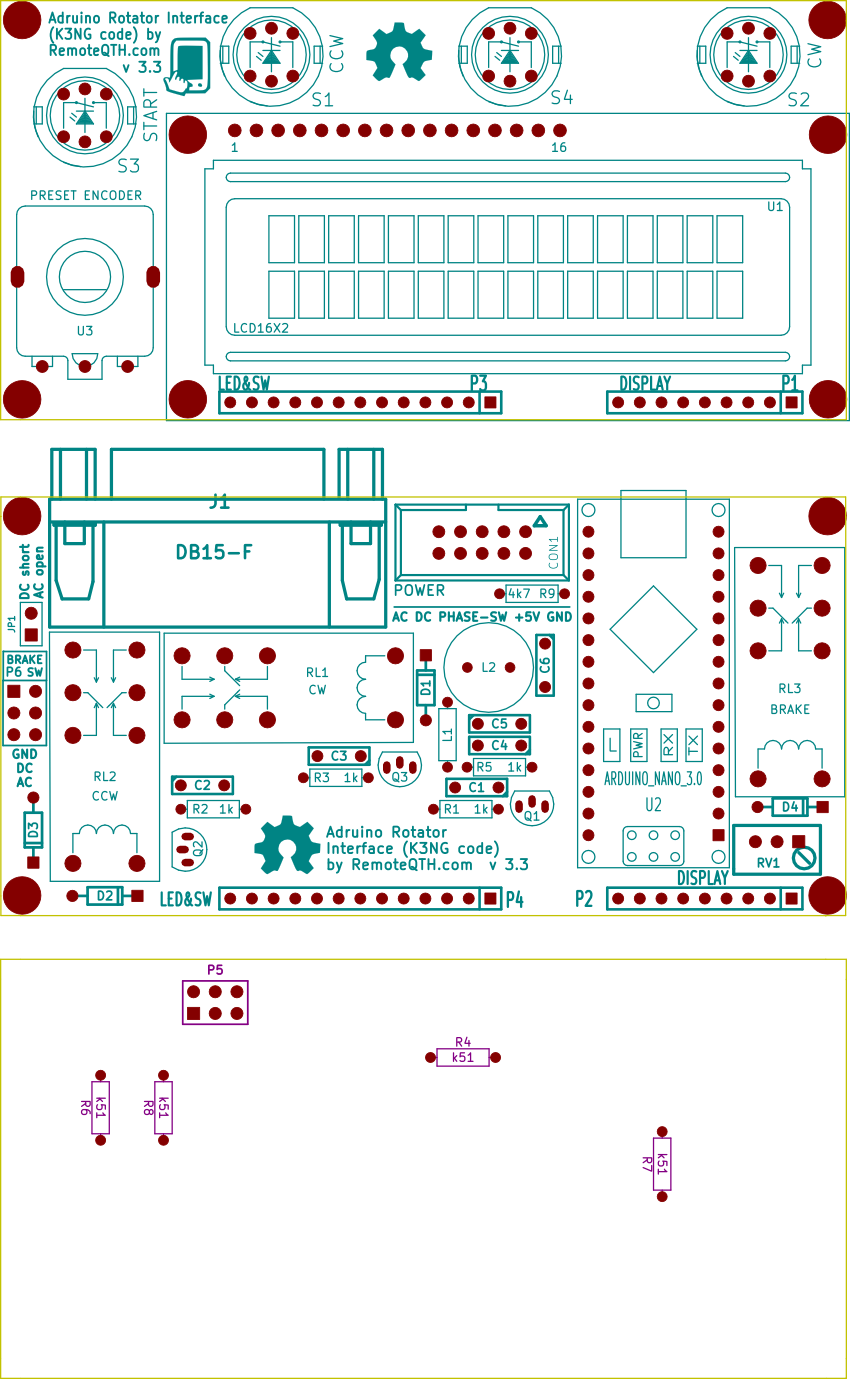

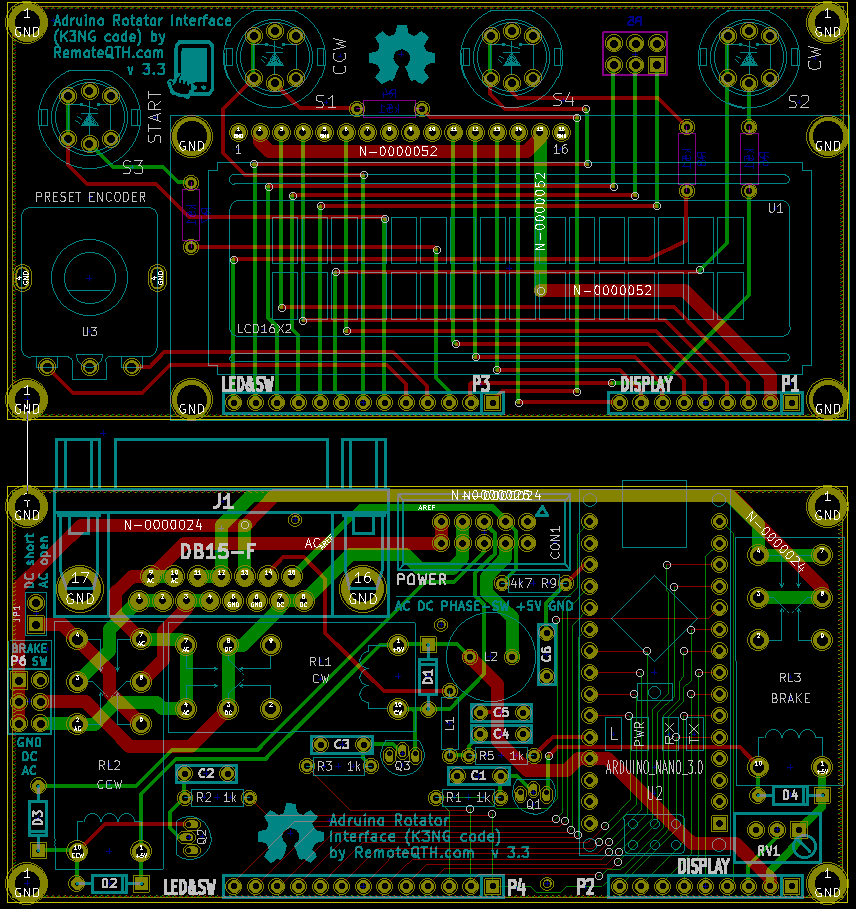

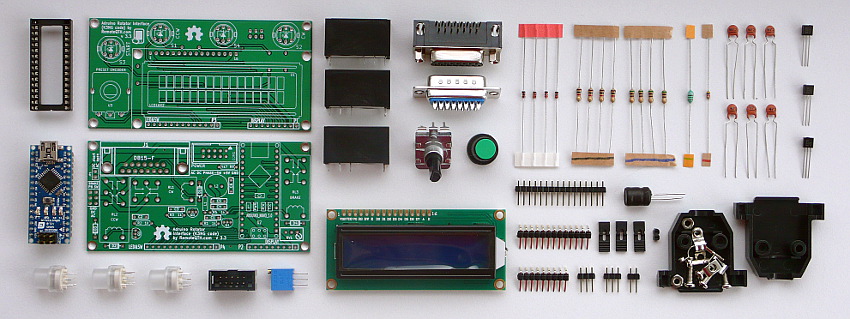

| Main and LCD PCB | two PCB |

| C1,C2,C3,C4,C5, C6 | capacitor 4n7 |

| D1,D2,D3,D4 | diode 1n4148 |

| L1 | inductor 150uH |

| L2 | inductor 220uH |

| R1,R2,R3,R5 | resistor 1k |

| R9 | resistor 4k7 |

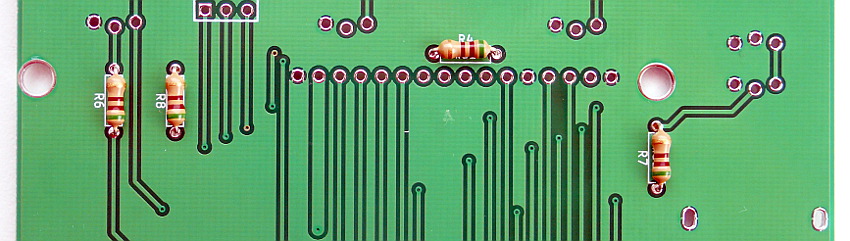

| R4,R6,R7,R8 | resistor 510R |

| RV1 | potenciometer 1k |

| Q1,Q2,Q3 | transistor BC547 |

| S1,S2,S3 | LED switch |

| RL1,RL2,RL3 | Relay |

| U1 | LCD 16X2 |

| U3 | preset encoder with knob |

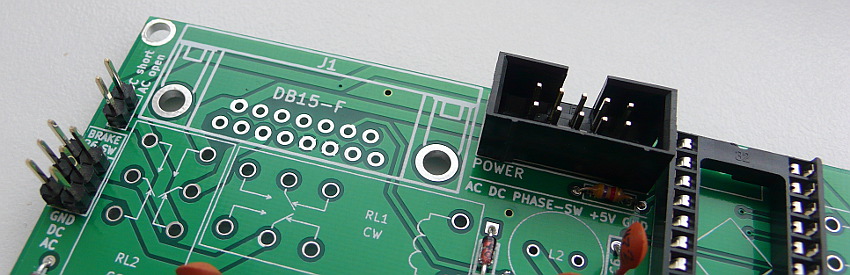

| J1 | DB15-F + DB15-M |

| CON1 | pin array 5x2 |

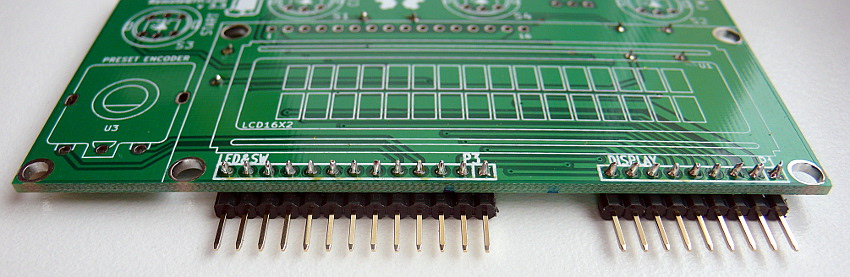

| P2+P1, P3+P4 | strip 9+13 pins 90° |

| P5 | pin array_3x2 |

| P6, JP1 | pins + jumper |

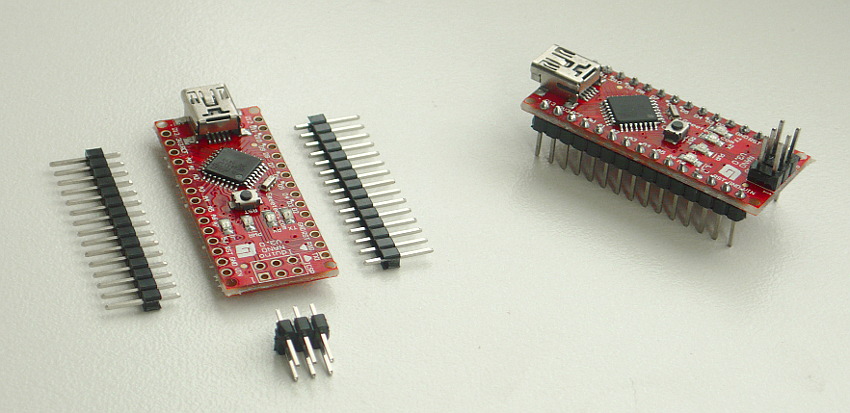

| U2 | Arduino nano 3.0 + socket |

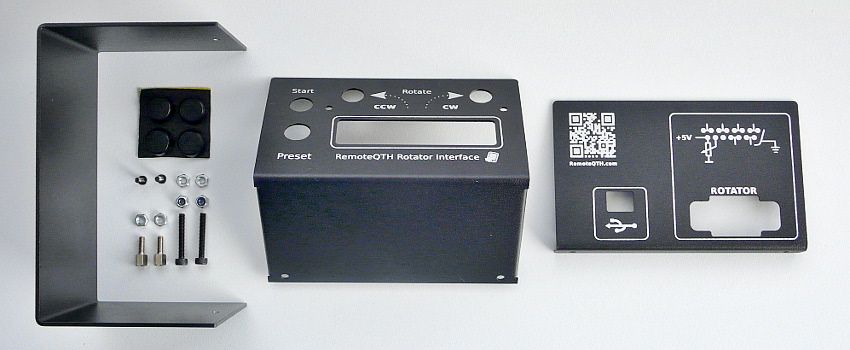

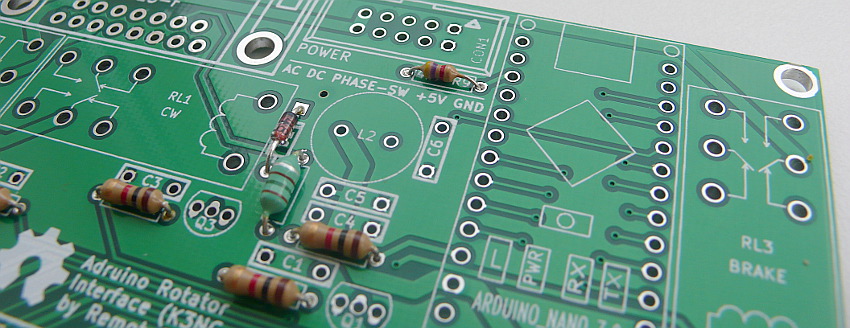

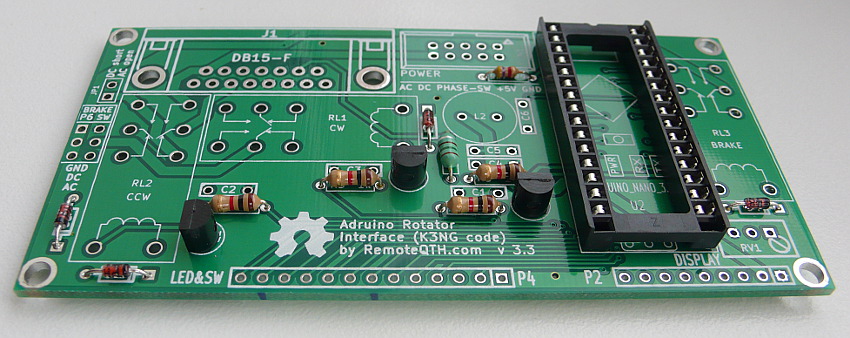

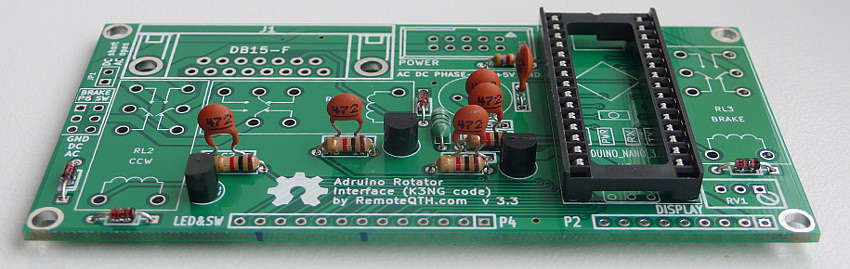

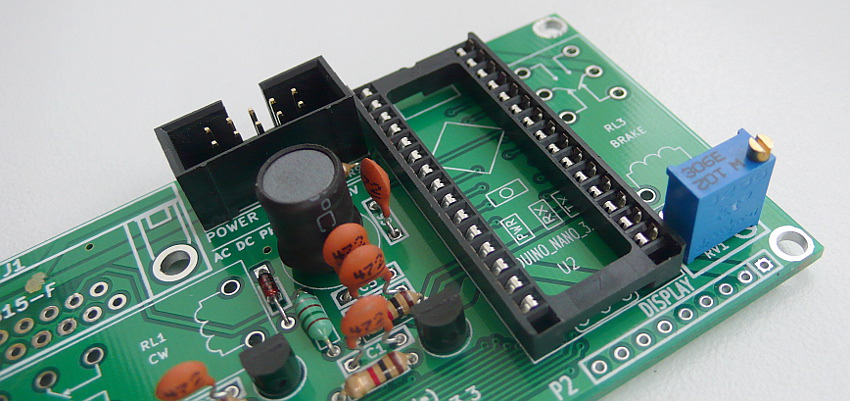

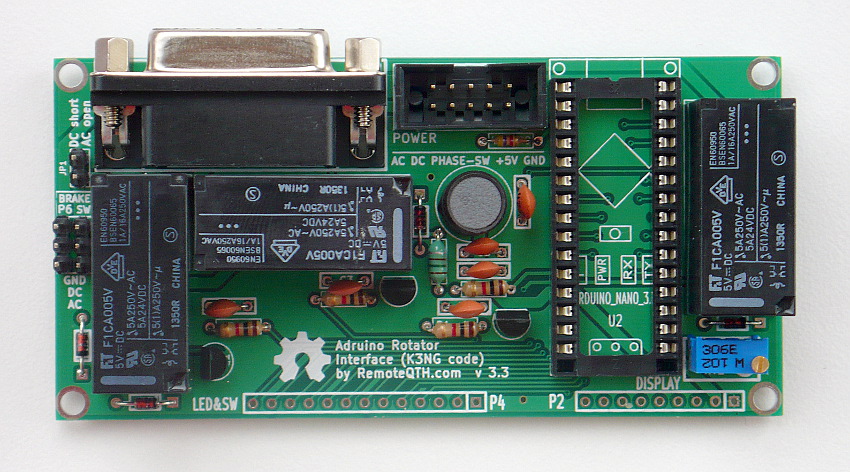

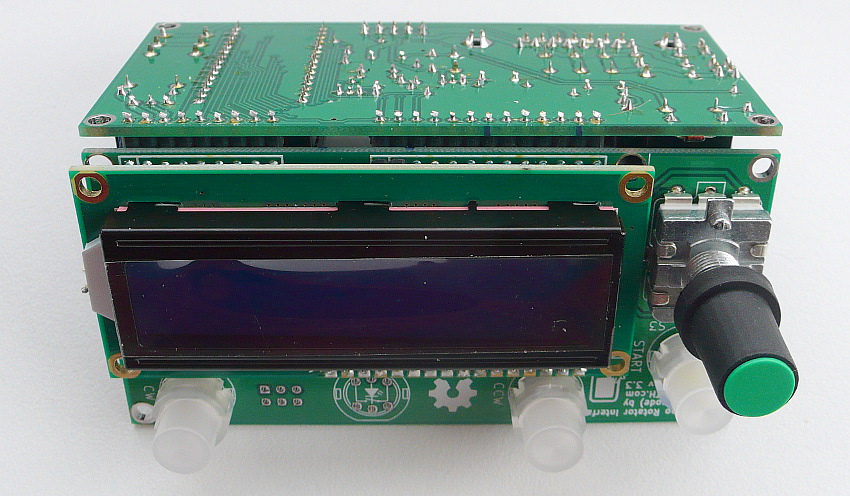

Assembly gallery

✔ All components

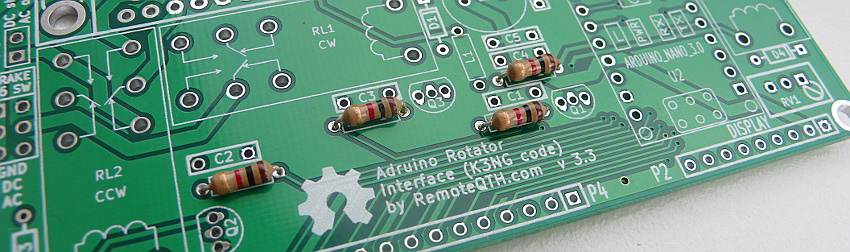

❏ Solder R4 R6 R7 R8 (marked in blue)

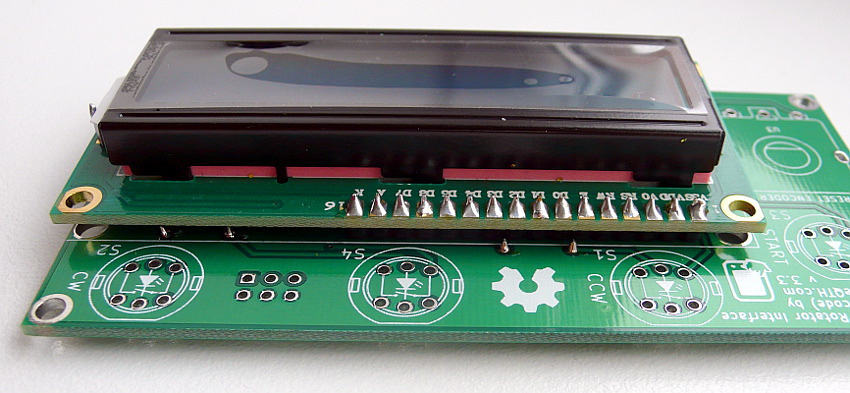

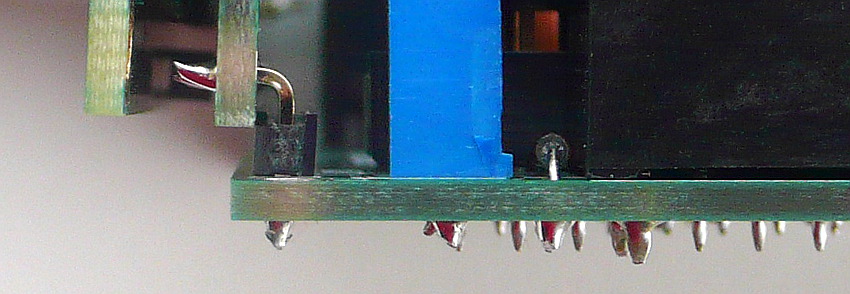

❏ 13 and 9 pins 90° strip

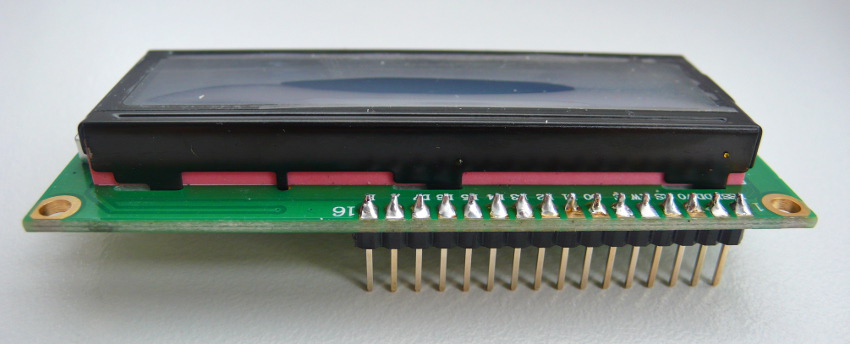

❏ 16 pins strip to LCD

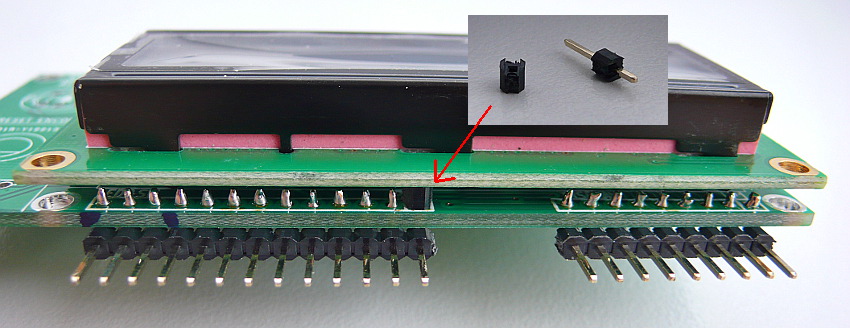

❏ Insulating spacer washers between LCD and PCB

❏ LCD module to PCB

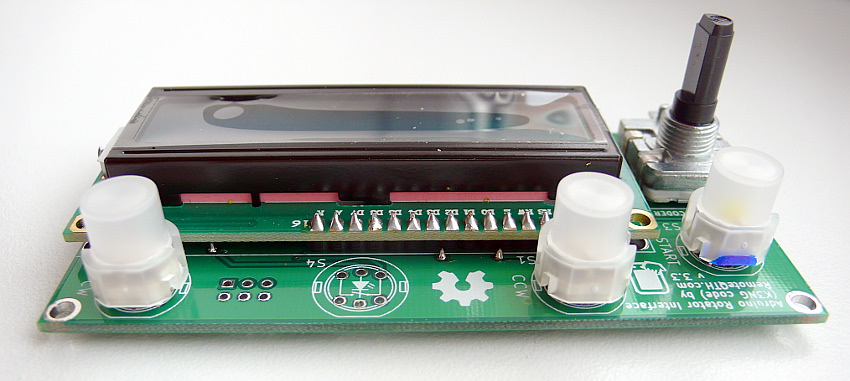

❏ CW, CCW and START switch (marked in blue) and preset encoder, Now front panel is final

❏ Next R1 R2 R3 R5 (marked in black) and R9 solder on main board

❏ D1 D2 D3 D4 (marked in red)

❏ L1 (marked in green) R9 (marked in red)

❏ Q1 Q2 Q3 and Arduino socket

❏ C1 C2 C3 C4 C5 and C6

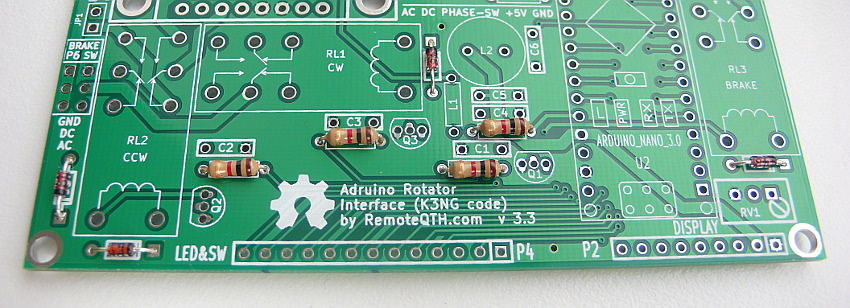

❏ JP1 P6 CON1

❏ L2 RV1

❏ RL1 RL2 RL3 J1

❏ solder front panel via pin strip

❏ Last solder Arduino Nano pins

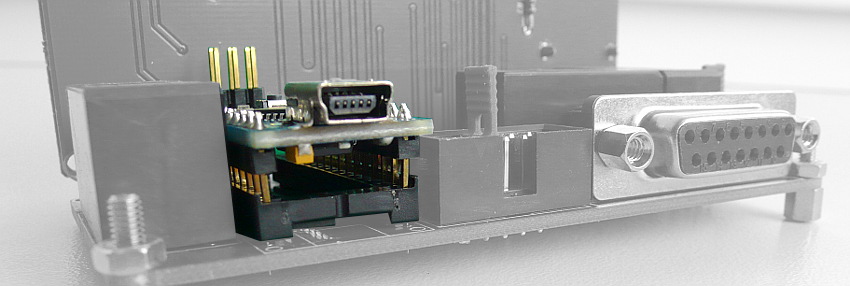

❏ Plug Arduino Nano to socket U2

❏ after power up, preset LCD contrast with potentiometer RV1

Firmware

Next step - you need upload firmware to arduino nano.

For beginners Getting Started with Arduino

You can configure firmware from master tree Arduino firmware by K3NG

Or download preconfigured version

You must configure the firmware, because it contains the settings of your rotator, such as azimuth range, etc.

Please read author documentation

- If the LCD displays instead of the character degree (°) lower case "alpha" (α), find in source code all string 'char(223)' and replace to 'char(178)'.

Power

The entire module can be powered from USB only, but there is a voltage drop, it is better to use an external +5V source, or a DC/DC converter and cut the power to the attached USB cable.

Pin 3 in CON1 (+5 volts input to supply measure the azimuth)- input stabilized voltage from power board This pin may be short connected (as picture below) with pin4 CON1 (+5 volts to interface), then the voltage measurement uses a common 5V voltage from the power supply module.

Connect DC Rotator (DB15 female) and power inputs

- Need three jumper

- short DC position P6 jumper switch

- short JP1 jumper

- short PHASE-SW (center) position CON1

- connect example

- Yaesu G800

pin DB15 G800 unit ------------------------- 1+2 -> 5 3+4 -> 4 15 -> 1 14 -> 2 GND -> 3

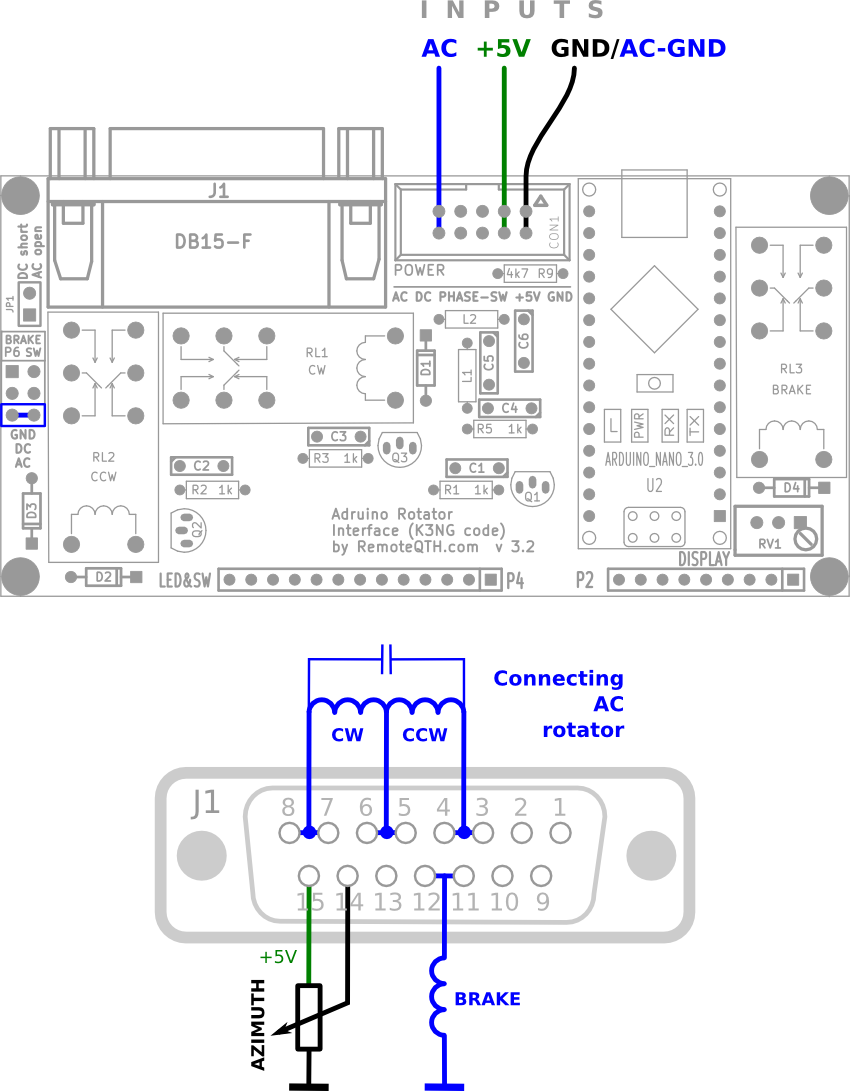

Connect AC Rotator (DB15 female) and power inputs

Diagram for the common AC and +5V ground

- Need one jumper

- short AC position P6 jumper switch

Solutions for HAM IV rotator by VA2NG

External addon for use with grounded center potentiometer like HAM IV rotor.

Comparsion output voltage of the pot with 200 ohms and 1500 ohms resistor. The curve is more flat = less position error.

Other inspiration potentiometer with grounded center

- Resolving without compromise - the solution is mechanically remove grounded center and connect by three wire

- hardware addon.

- Add resistor with grounded two wire potentiometer - this solutions produce nonlinearity voltage. You can use calibration table

- Circuits

Diagram for the different AC and +5V ground

Use with original control box

Two wire azimuth potentiometer hardware addon from DM2RM

- R1 = your Azimuth potentiometer

- Vaz = about 3,75V (input 5V - loss on controller)

- R2 = R1/(Vaz/1,25-1)

- Accurate measurement can be achieved by reducing voltage AREF input to the maximum value of the azimuth potentiometer (Vaz).

- LM317 rezistor online calculator

Ten turn azimuth potentiometer (one turn used)

- Need negative and positive voltage source

- Set potentiometer bridge from 0 to +5V output

- Left trimmer set a 0V after full CCW rotate

- by right trimmer, set the +5V after full CW rotate

- Repeat until the voltage agree

- Circuit

Control software

- PstRotator for Windows

- RemoteQTH server image for Raspberry PI - web interface

- Even software supporting Yaesu GS-232 protocol...