Rotator module version 3.3

- Power

- Connect DC Rotator (DB15 female) and power inputs

- Connect AC Rotator (DB15 female) and power inputs

- Connection examples

- Control software

Components of Multi rotator controller server

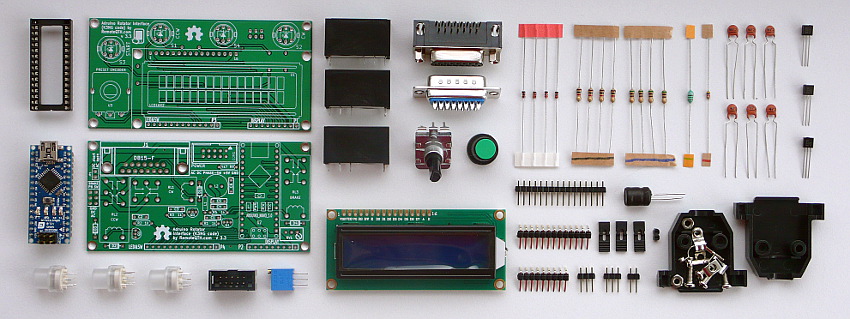

Part list

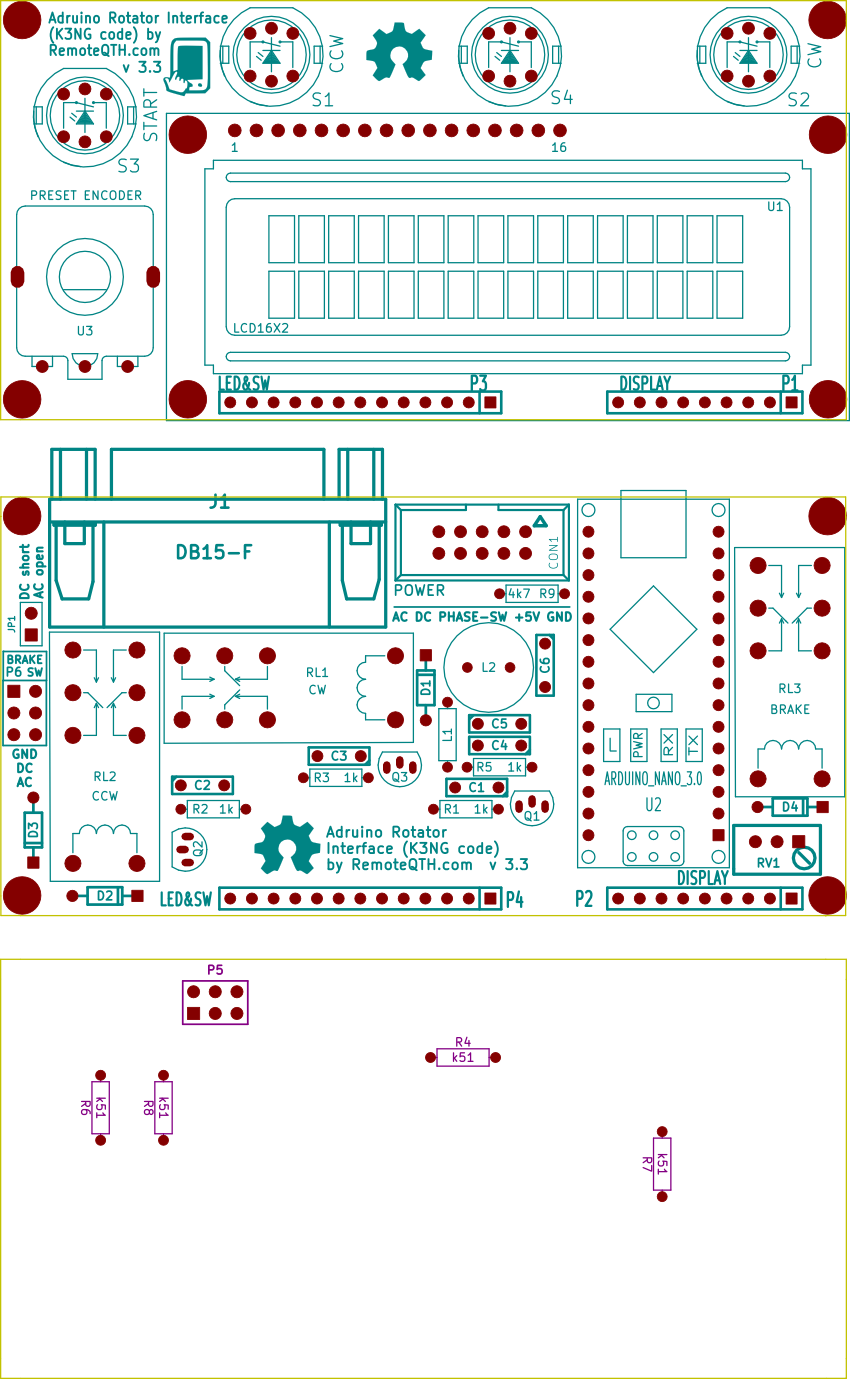

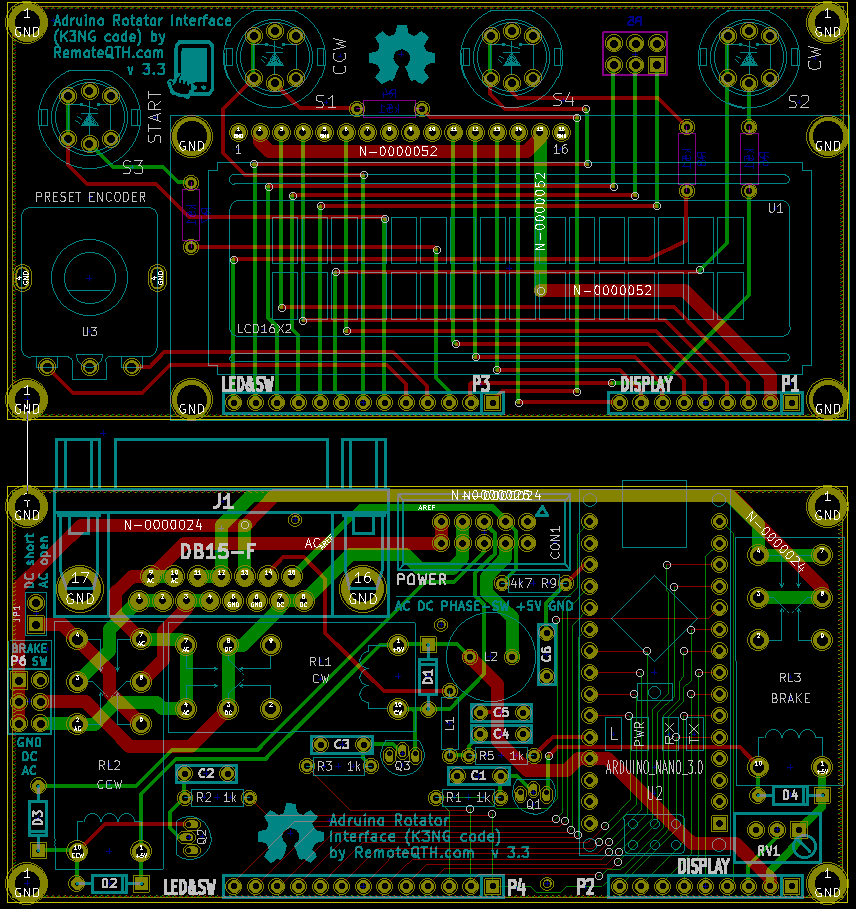

| Main and LCD PCB | two PCB |

| C1,C2,C3,C4,C5, C6 | capacitor 4n7 |

| D1,D2,D3,D4 | diode 1n4148 |

| L1 | inductor 150uH |

| L2 | inductor 220uH |

| R1,R2,R3,R5 | resistor 1k |

| R9 | resistor 4k7 |

| R4,R6,R7,R8 | resistor 510R |

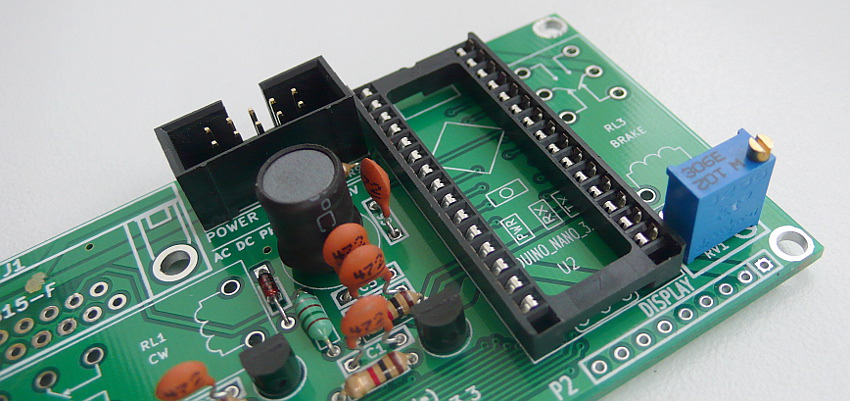

| RV1 | potenciometer 1k |

| Q1,Q2,Q3 | transistor BC547 |

| S1,S2,S3 | LED switch |

| RL1,RL2,RL3 | Relay |

| U1 | LCD 16X2 |

| U3 | preset encoder with knob |

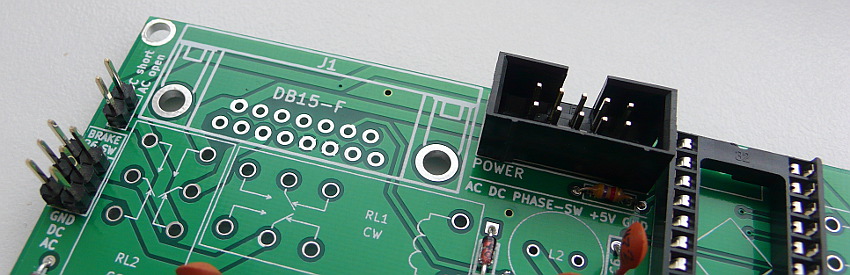

| J1 | DB15-F + DB15-M |

| CON1 | pin array 5x2 |

| P2+P1, P3+P4 | strip 9+13 pins 90° |

| P5 | pin array_3x2 |

| P6, JP1 | pins + jumper |

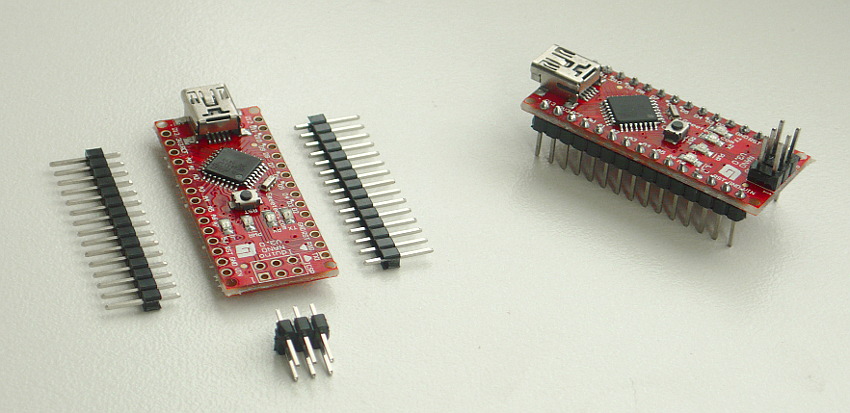

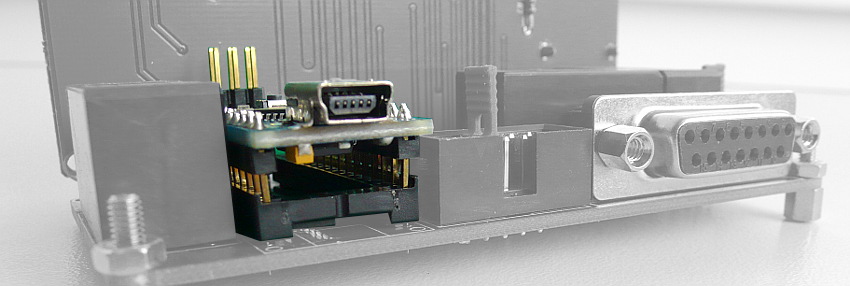

| U2 | Arduino nano 3.0 + socket |

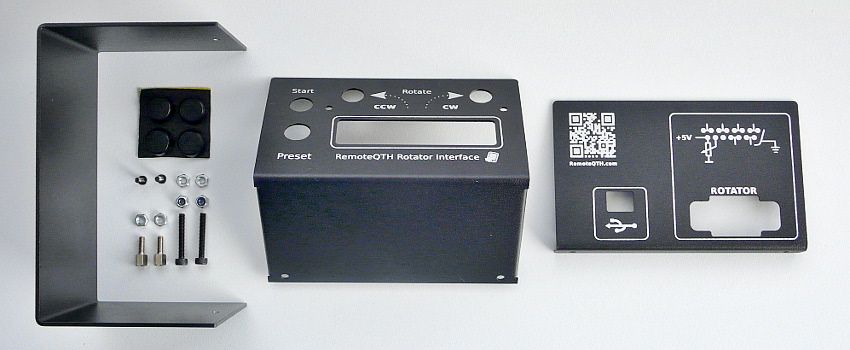

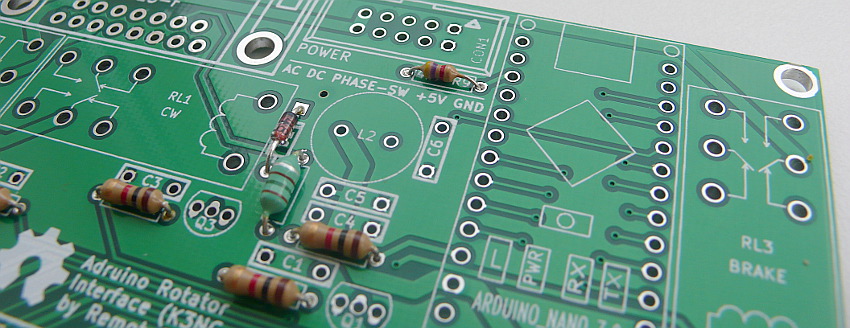

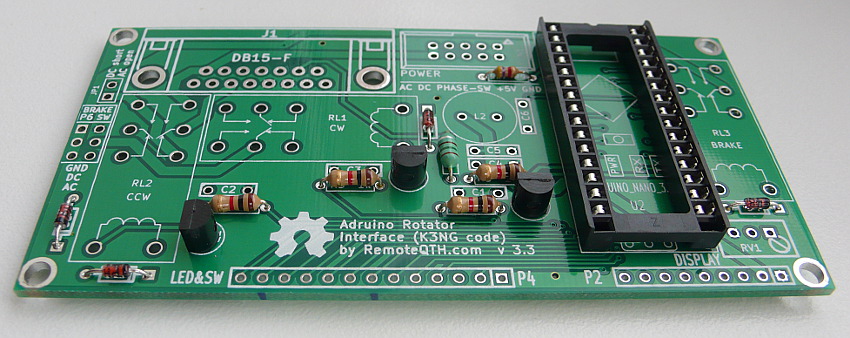

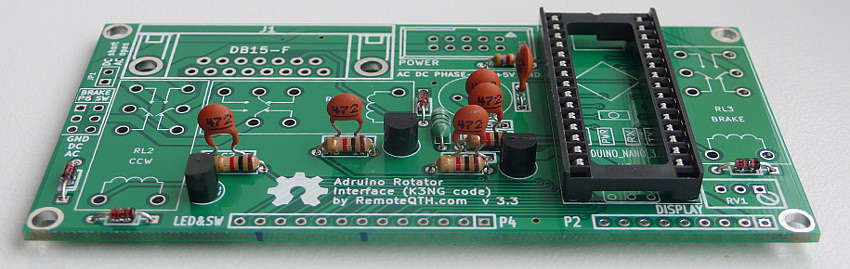

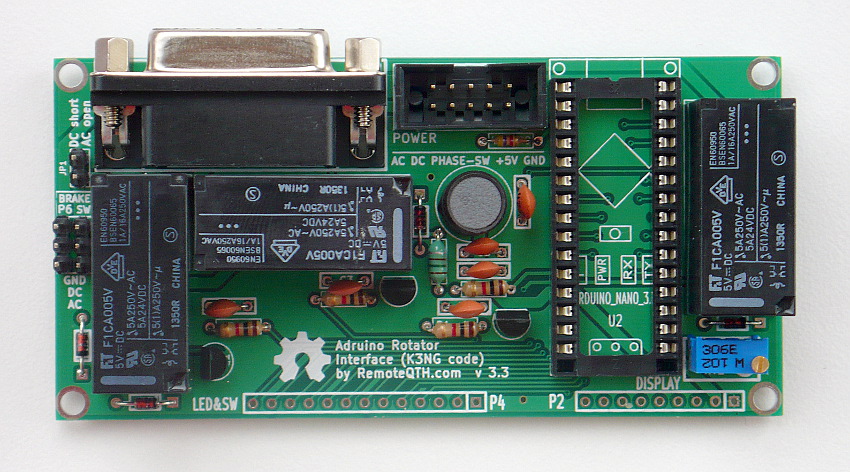

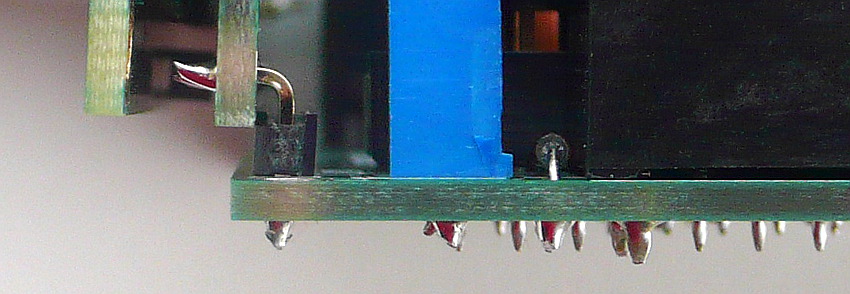

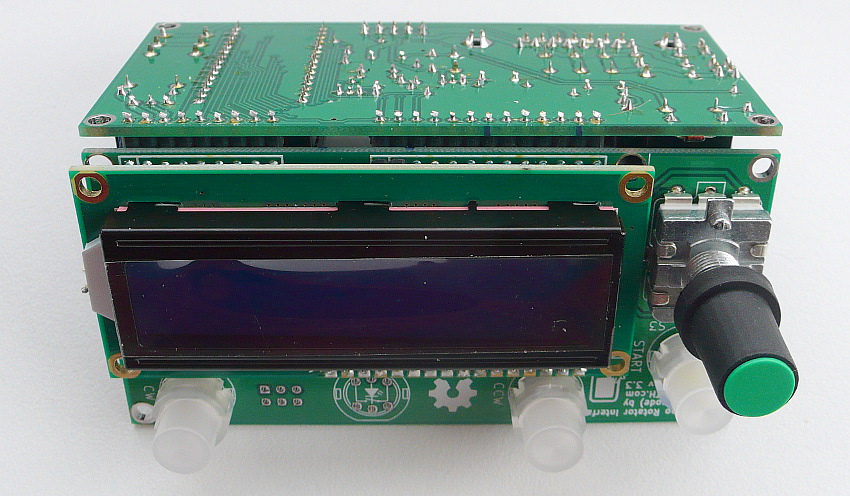

Assembly gallery

✔ All components

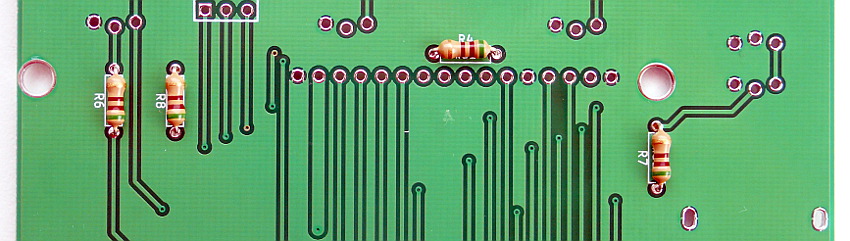

❏ Solder R4 R6 R7 R8 (marked in blue)

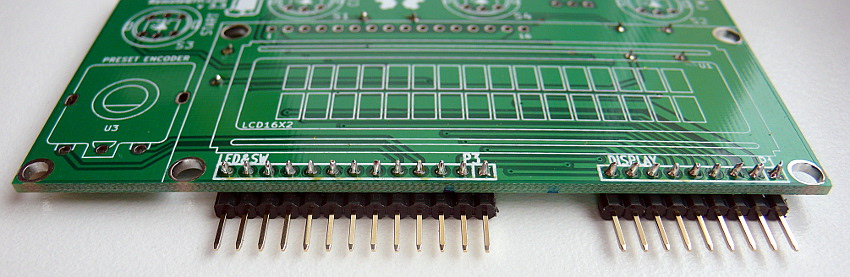

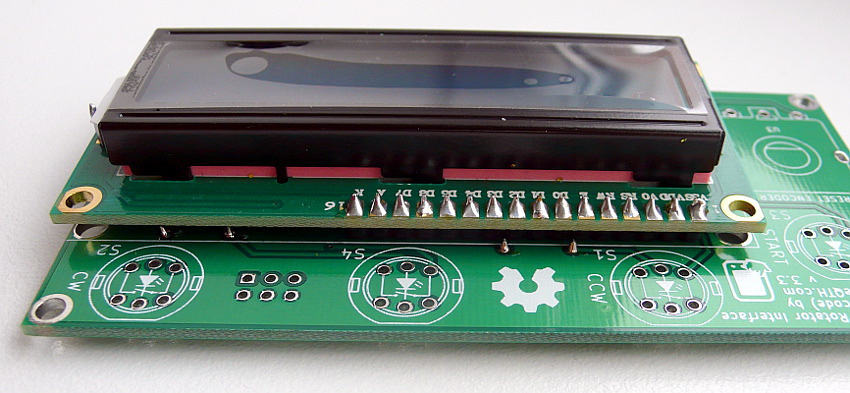

❏ 13 and 9 pins 90° strip

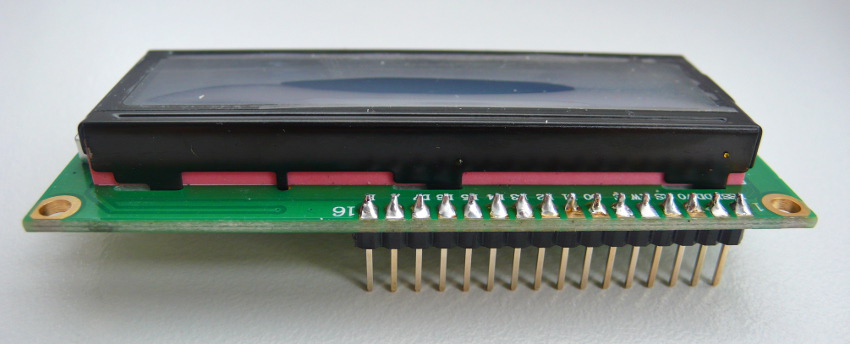

❏ 16 pins strip to LCD

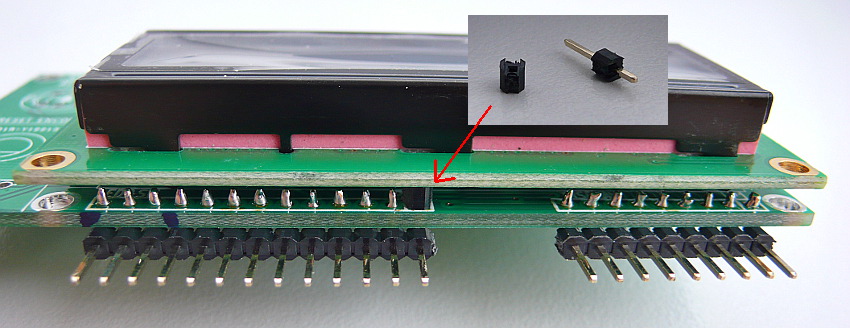

❏ Insulating spacer washers between LCD and PCB

❏ LCD module to PCB

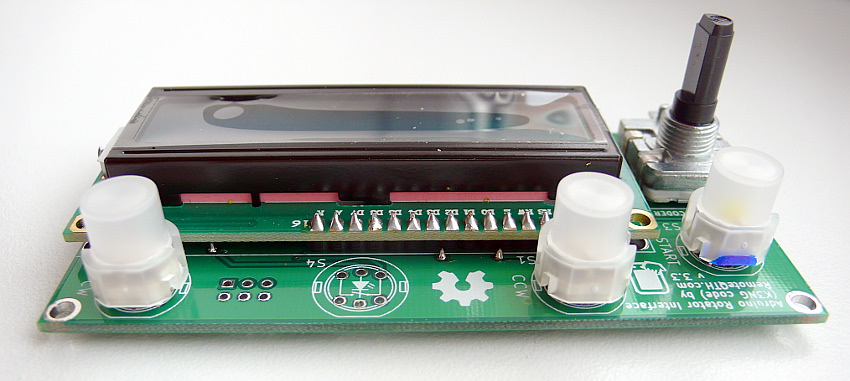

❏ CW, CCW and START switch (marked in blue) and preset encoder, Now front panel is final

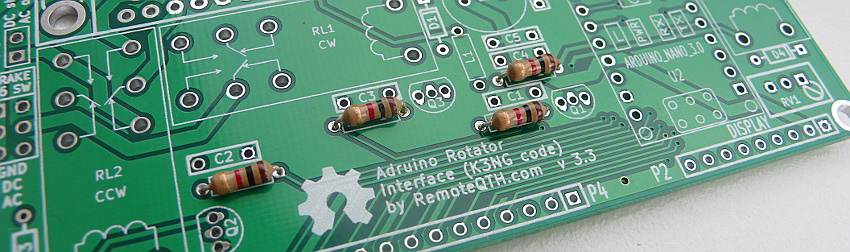

❏ Next R1 R2 R3 R5 (marked in black) and R9 solder on main board

❏ D1 D2 D3 D4 (marked in red)

❏ L1 (marked in green) R9 (marked in red)

❏ Q1 Q2 Q3 and Arduino socket

❏ C1 C2 C3 C4 C5 and C6

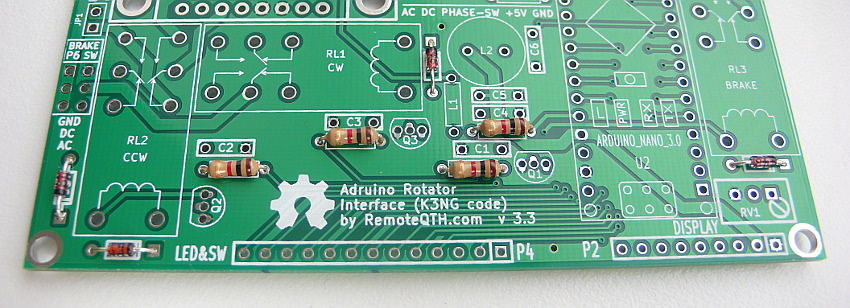

❏ JP1 P6 CON1

❏ L2 RV1

❏ RL1 RL2 RL3 J1

❏ solder front panel via pin strip

❏ Last solder Arduino Nano pins

❏ Plug Arduino Nano to socket U2

❏ after power up, preset LCD contrast with potentiometer RV1

Firmware

For beginners Getting Started with Arduino

- Download and install Arduino IDE

- Install library

- Download firmware from master tree Web | GitHub.

- requires disable in rotator_features.h (TNX GI1MIC)

#define DEBUG_DUMP

- Or download preconfigured version

- 2019-01-03.zip (TNX GI1MIC)

- 2015-02-24-4RQ.zip - modified version for used with RemoteQTH server web interface.

- 2015-02-24.zip

- 2014-07-08.zip

- 2013-10-26.zip

- Configure by author documentation - contains the settings of your rotator, such as azimuth range, etc.

- Version 2019-01-03 - If do not show degree character (°), change in file rotator_settings.h settings to

#define DISPLAY_DEGREES_STRING "\xB2"

- Version 2015-02-24 - If the LCD displays instead of the character degree (°) lower case "alpha" (α), find in source code all string 'char(223)' and replace to 'char(178)'.''

- Connect USB cable cable between interface and PC

- Select menu Tools/Board:Arduino Nano

- Select menu Tools/Processor: ATmega328P (Old Bootloader)

- Select menu Tools/Port/YOUR-CONNECTED-PORT

- Upload firmware

Third party software

Power

Power inputs are available on both connector CON1 and DB15-J1.

| Power inputs | CON1 | DB15-J1 |

| AC | pin 9+10 | pin 9+10 |

| DC | pin 7+8 | pin 7+8 |

| +5V | pin 3+4 | pin 15 |

| GND | pin 1+2 | pin 5+6 |

- 5V - the entire module can be powered from USB only, but there is a voltage drop, it is better to use an external +5V source, or a DC/DC converter and cut the power to the attached USB cable.

- DC/DC switch add-on for stable 5V power from USB

- CON1 is for power distribution if use with Rapsberry PI gpio board in server.

- In sigle interface it is used only phase jumper (Pin 5+6) and short 3+4. All other pins available also in DB15-J1 connector - see on schematics.

- Pin 3 in CON1 (+5 volts input to supply measure the azimuth)- input stabilized voltage from power board This pin may be short connected (as picture below) with pin4 CON1 (+5 volts to interface), then the voltage measurement uses a common 5V voltage from the power supply module.

Connect DC Rotator (DB15 female) and power inputs

- Need three jumper

- short DC position P6 jumper switch

- short JP1 jumper

- short PHASE-SW pin 5+6 (center) position CON1

- short +5V pin 3+4 CON1

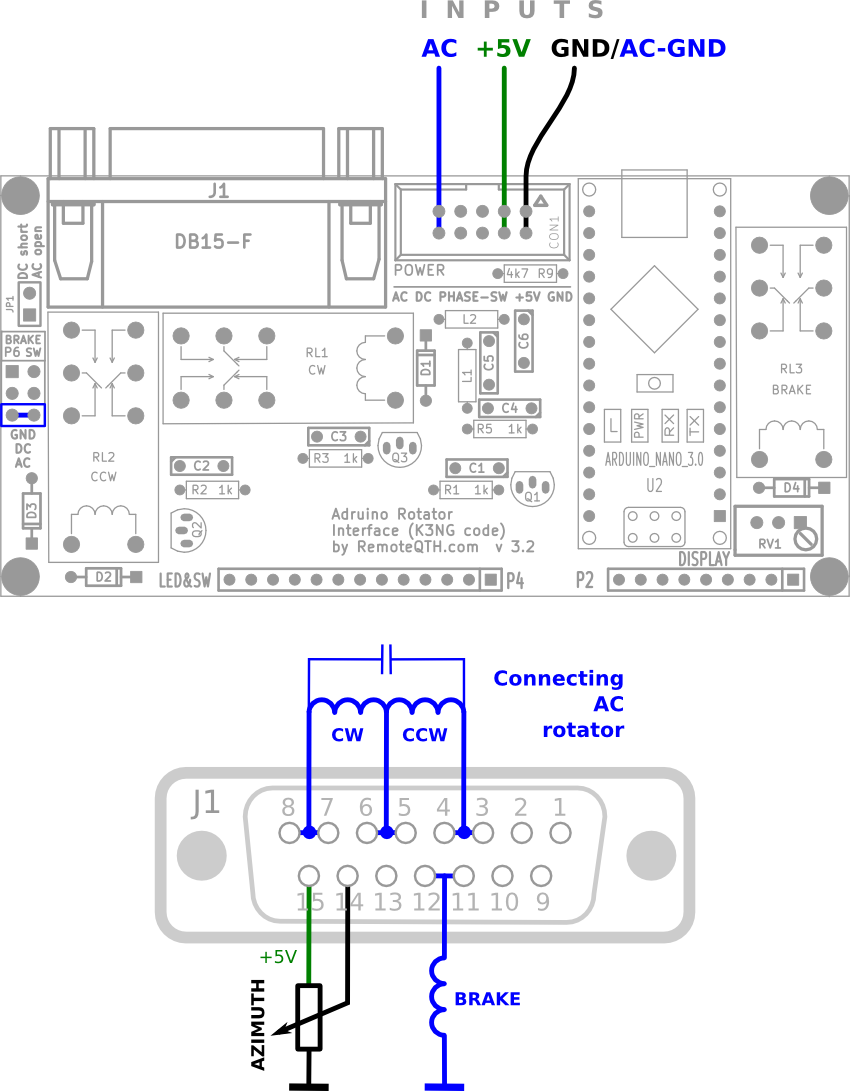

Connect AC Rotator (DB15 female) and power inputs

Diagram for the common AC and +5V ground

- Need one jumper

- short AC position P6 jumper switch

- short +5V pin 3+4 CON1

Diagram for the different AC and +5V ground

- Need one jumper

- short AC position P6 jumper switch

- short +5V pin 3+4 CON1

Connection examples

Use with original control box

- OH3BHX firmware for G400RC and connection

- Yaesu G-5400B

- Yaesu G-2800DXA

- DF2LH solution with Kenpro G800-1000SDX

- Yaesu G800

pin DB15 G800 unit ------------------------- 1+2 -> 5 3+4 -> 4 15 -> 1 14 -> 2 GND -> 3

CDE/HyGain HAM IV (grounded center potentiometer)

- Resolving without compromise - mechanically remove grounded center and connect by three wire

- Solutions by VA2NA - external add-on

- Solutions by DM2RM - external add-on

- Add resistor with grounded two wire potentiometer - this solutions produce nonlinearity voltage. You can use calibration table - is not recommended.

Ten turn azimuth potentiometer (one turn used)

- Need negative and positive voltage source

- Set potentiometer bridge from 0 to +5V output

- Left trimmer set a 0V after full CCW rotate

- by right trimmer, set the +5V after full CW rotate

- Repeat until the voltage agree

- Circuit

Control software

- PstRotator for Windows

- RemoteQTH server image for Raspberry PI - web interface

- gRotor

- Even software supporting Yaesu GS-232 protocol...